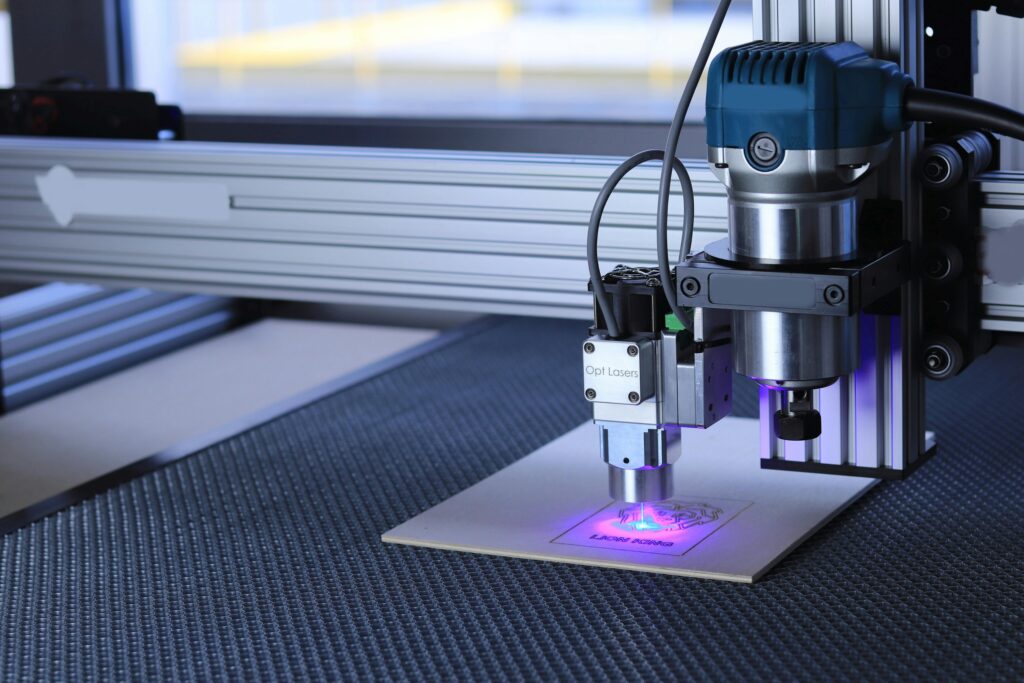

Laser cutting for sheet metal provide high-precision cuts, smooth edges, and complex shapes with minimal waste. They enable faster production, flexible design options, and consistent quality for a wide range of industrial and fabrication needs.

CNC bending shapes sheet metal with precision and consistency, enabling accurate angles and complex forms for enclosures, brackets, and structural parts.

CNC punching creates holes, slots, and patterns quickly and efficiently in sheet metal, supporting both functional and decorative designs.

Powder coating finishes metal surfaces with a durable, protective, and attractive layer, offering resistance to corrosion, scratches, and fading.

Tapping forms threaded holes in metal parts, allowing bolts and screws to be fastened securely during assembly.

PEM hardware installation secures fasteners such as nuts, studs, and standoffs directly into sheet metal, providing strong, reliable connections without welding.

Welding joins metal parts into strong, permanent structures, ensuring durability and reliability for frames, enclosures, and custom fabrications.